Why Machinists Need Bespoke Tool Storage Solutions

Share

You rely on precision and efficiency in your machining work, and bespoke tool storage solutions are essential to achieving that. They enable you to quickly locate and access the tools you need, optimize your workflow, and guarantee easy retrieval of frequently used items. With a customized storage system, you'll reduce time spent searching for tools, enhance your focus on machining tasks, and improve overall work performance. By tailoring your storage to your unique workshop requirements, you'll uncover even more ways to boost productivity and efficiency, and it's just a matter of exploring these benefits further.

Key Takeaways

• Machinists require bespoke tool storage solutions to optimize workflow and efficiency, ensuring easy access to frequently used tools and reflecting their unique workshop culture.

• Customized storage solutions help machinists protect valuable tools and assets, mitigating risks and reducing the likelihood of damage or loss.

• Bespoke tool storage enables machinists to maximize limited workshop space, assigning a home to each tool and machine, and optimizing floor plan layout.

• Tailored storage solutions streamline workshop organization systems, reducing waste, and increasing productivity, while also improving task quality and profitability.

• By having a customized tool storage solution, machinists can focus on precision craftsmanship, enhance their skills, and make data-driven decisions to drive business growth.

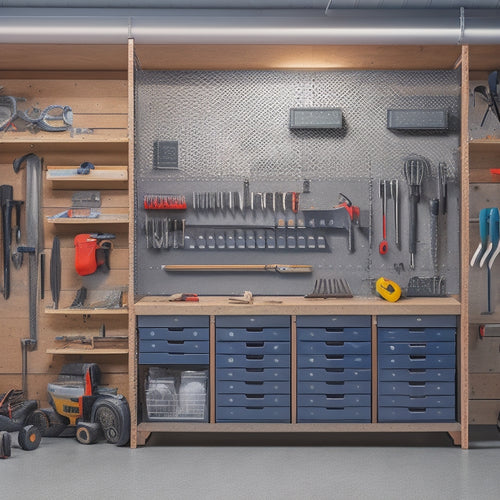

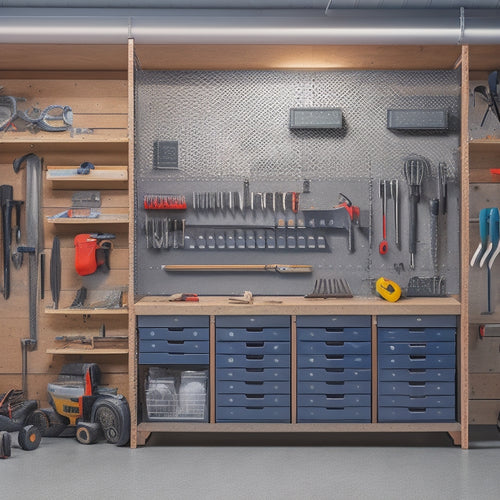

Customized Tool Storage for Machinists

Your workshop's productivity hinges on the organization and accessibility of your tools, which is why customized tool storage solutions are essential for machinists like you.

A well-designed storage system allows you to quickly locate the tools you need, saving time and reducing frustration. By catering to your unique tool preferences, you can optimize your workflow and increase efficiency.

For instance, if you frequently use a specific drill bit, a customized storage solution can guarantee it's always within easy reach. Additionally, a tailored storage system can also reflect your workshop culture.

Are you a tidy machinist who values a clutter-free workspace, or do you thrive in a more chaotic environment? Either way, a customized storage solution can be designed to accommodate your work style.

Meeting Unique Workshop Requirements

As you tailor your workshop to meet your unique tool preferences, you'll likely encounter specific requirements that demand innovative storage solutions. Your workshop's layout and design must cater to your distinct needs, guaranteeing that every tool is within easy reach. This is where bespoke tool storage solutions come into play.

By integrating your equipment and machines, you can create a seamless workflow that enhances your productivity. Additionally, incorporating workshop ergonomics into your storage design ensures that your workstations are optimized for comfort and efficiency.

When designing your bespoke storage solutions, consider the specific requirements of your equipment and tools. For instance, do you need customized cabinets for storing specialized cutting tools or precision instruments? Perhaps you require mobile storage units that can be easily moved around the workshop to facilitate equipment integration.

Whatever your needs, a well-designed storage system can help you stay organized, reduce clutter, and maintain a safe working environment. By meeting your unique workshop requirements, you can create a space that's tailored to your specific needs, allowing you to focus on what matters most – producing high-quality work.

Boosting Productivity and Efficiency

In addition to streamlining your tool storage, you can shave precious minutes off your workflow, freeing up time to focus on the precision craftsmanship that drives your business forward.

Every machinist knows that time is money, and bespoke tool storage solutions can help you optimize your workflow like never before. With a customized storage system, you can quickly locate the tools you need, reducing downtime and increasing productivity. This, in turn, enables you to take on more projects, meet deadlines, and enhance your skills as a machinist.

By implementing effective time tracking, you can identify areas for improvement and make data-driven decisions to optimize your workflow further. Additionally, with the extra time you'll save, you can focus on skill enhancement, experimenting with new techniques, and staying up-to-date with the latest industry developments.

Protecting Valuable Tools and Assets

You invest significant resources in acquiring high-quality tools and assets, so it's essential that you safeguard them from damage, loss, or theft. A single incident can result in substantial financial losses, not to mention the disruption to your workflow and reputation.

That's why it's vital to conduct a thorough risk assessment to identify potential vulnerabilities in your workshop. This will help you prioritize the measures needed to mitigate those risks.

Having adequate insurance coverage is also important. It's not just about replacing lost or damaged tools, but also about ensuring business continuity.

With bespoke tool storage solutions, you can greatly reduce the likelihood of damage or loss. Customized storage systems can be designed to accommodate your unique toolset, ensuring that each item is properly secured and protected.

Streamlining Workshop Organization Systems

Optimizing your workshop's layout and organization is crucial for maximizing efficiency, reducing waste, and increasing productivity. You know that every minute counts, and a well-structured workshop can make all the difference. That's why you need to take a closer look at your workshop culture and identify areas for improvement. By doing so, you'll be able to streamline your organization systems and get more done in less time.

Process mapping is an excellent way to achieve this. By mapping out your workflows and processes, you can identify bottlenecks and inefficiencies that are holding you back. You'll be able to visualize your operations and pinpoint areas where you can improve, simplify, or eliminate tasks. This will enable you to optimize your workflow, reduce downtime, and increase output.

Furthermore, a well-mapped process will help you standardize tasks, reduce errors, and improve quality. By streamlining your workshop organization systems, you'll be able to create a more efficient, productive, and profitable work environment that allows you to focus on what matters most – delivering high-quality results.

Maximizing Limited Workshop Space

When you're working in a cramped workshop, every inch counts. To make the most of your limited space, you'll need to strategically plan your floor plan layout, optimize your workbench organization, and capitalize on available vertical space.

Optimizing Floor Plan Layout

Maximizing limited workshop space requires strategically assigning a home to each tool and machine, guaranteeing every square foot contributes to your productivity. You need to think critically about your work flow and space allocation to optimize your floor plan layout. This means identifying bottlenecks and areas where workflow is hindered by inefficient tool placement.

Here are three key considerations to keep in mind:

-

Tool frequency and proximity:

Place your most frequently used tools in easy-to-reach locations, reducing travel time and increasing productivity. -

Machine placement and workflow:

Position machines in a way that facilitates a smooth workflow, minimizing the need to backtrack or reposition tools and materials. -

Aisle clearance and navigation:

Guarantee sufficient aisle clearance to accommodate easy navigation, preventing congestion and accidents.

Streamlining Workbench Organization

Every machinist aims to transform their workbench into a highly efficient hub, where each tool has a designated spot and every inch of space is utilized to accelerate task completion. To achieve this, you need to streamline your workbench organization. A well-organized workbench enables you to quickly find the tools you need, reducing downtime and increasing productivity.

| Tool Category | Storage Solution | Benefits |

|---|---|---|

| Hand tools | Pegboard with hooks and bins | Easy access, visual workflow |

| Power tools | Slotted shelving with dividers | Ergonomic layout, reduced clutter |

| Measuring tools | Drawer organizers with dividers | Quick retrieval, reduced searching |

Utilizing Vertical Space

You can greatly enhance your workshop's capacity by leveraging vertical space, which is often underutilized in machining environments. By making the most of your walls and ceiling, you can free up valuable floor space and improve overall efficiency. This is especially important in smaller workshops where every square foot counts.

Here are three ways to maximize your vertical space:

-

Install wall anchors: These allow you to hang tool organizers, bins, and other storage solutions, keeping frequently used items within easy reach.

-

Utilize ceiling hooks: Suspend heavy tools, equipment, or even entire workstations from the ceiling, freeing up floor space and reducing clutter.

-

Invest in vertical shelving: Customizable shelving units can be designed to fit your specific needs, providing ample storage for tools, materials, and supplies.

Frequently Asked Questions

Can Bespoke Tool Storage Solutions Be Adapted for Small Workshops?

You'll be pleased to know that bespoke tool storage solutions can be adapted for small workshops, focusing on space optimization and workshop ergonomics, ensuring efficient use of limited space and streamlining your workflow.

What Is the Typical Lead Time for Custom Tool Storage Design and Build?

You'll typically wait 4-6 weeks for custom tool storage design and build, depending on complexity, with 2-3 design phases and production schedules tailored to your needs, ensuring a seamless process from concept to installation.

Are Bespoke Storage Solutions Compatible With Existing Workshop Layouts?

"Think your workshop's too unique for bespoke storage? Think again! You'll be pleased to know that custom solutions seamlessly integrate with your existing layout, even facilitating workshop renovation and layout optimization, to boost your productivity."

Can Customized Storage Solutions Be Integrated With CNC Machines?

You'll find that customized storage solutions can seamlessly integrate with CNC machines, streamlining your automated workflow through a user-friendly machine interface that optimizes tool access and reduces production downtime.

Are Bespoke Tool Storage Solutions Suitable for Mobile Workshops?

You're worried bespoke storage won't fit in your mobile workshop, but don't let mobile constraints hold you back. You'll find that tailored solutions adapt to your workshop dynamics, ensuring tools are within reach, and workflow efficiency isn't compromised.

Related Posts

-

Best Organizing Tools for a Clutter-Free Space

You're on a mission to change your cluttered space into a peaceful oasis, and you're looking for the best organizing ...

-

Building a Wall Tool Storage System

You're about to create a customized wall tool storage system that streamlines your workflow. Start by clearing your w...

-

Top 7 Parts Tray Organizers for Productivity

You can optimize your workspace and enhance productivity with the right parts tray organizer, which can help you cate...