What Are the Garage Workshop Layout Mistakes to Avoid

Share

When designing your garage workshop layout, beware of common mistakes that can hinder efficiency and safety. Inadequate workspace allocation can lead to clutter and wasted space, while poor tool placement can cause frequent repositioning and wasted time. Insufficient storage solutions can lead to clutter buildup, and inefficient workflow design can create obstacles and distractions. Ignoring ergonomic considerations can lead to fatigue and injury, while disregarding safety precautions can put you at risk of electrical shock, fire, and other hazards. To avoid these mistakes, prioritize workspace allocation, tool placement, storage, workflow design, ergonomics, and safety - and uncover the key to a well-functioning garage workshop that adapts to your changing needs.

Key Takeaways

- Inefficient workspace allocation and utilization can lead to wasted space, overcrowding, and clutter, hindering movement and workflow.

- Failing to prioritize tool accessibility and organization can result in clutter accumulation, tripping hazards, and reduced focus.

- Inadequate storage solutions can lead to clutter buildup, creating hazards and inefficiencies, and ignoring the need for clear pathways can cause accidents.

- Poor workflow design and efficiency can lead to obstacles, distractions, and fatigue, reducing productivity and increasing the risk of injury.

- Ignoring ergonomic considerations, safety precautions, and future growth needs can result in injury, accidents, and costly upgrades.

Inadequate Workspace Allocation

With a garage workshop, every square foot counts, and inadequate workspace allocation can lead to frustration and inefficiency. You need to optimize your workspace dimensions to guarantee you have enough room to move around comfortably and work on projects efficiently.

Start by identifying your most frequently performed tasks and prioritize them. This will help you determine how much space to allocate for each task. Consider the size of your tools and equipment, as well as the space needed for material storage and movement.

Next, assess your available space and allocate it accordingly. Consider creating zones for specific tasks, such as a woodworking area, a metalworking area, or a cleaning and maintenance area.

Within each zone, allocate space for the tools and equipment needed for that task. Remember to leave enough space between zones for easy movement and to prevent clutter buildup.

Poor Tool Placement Strategy

Now that you've optimized your workspace allocation, it's time to focus on the placement of your tools. A poor tool placement strategy can lead to inefficiencies, accidents, and frustration. To avoid this, prioritize tool accessibility by placing frequently used tools in easy-to-reach locations. This guarantees you can quickly access the tools you need, reducing the risk of accidents caused by overreaching or straining.

Implement workspace zoning by grouping similar tools together, such as all woodworking tools in one area and metalworking tools in another. This helps maintain a clean and organized workspace, reducing the risk of tripping hazards and allowing you to focus on the task at hand.

Additionally, consider the "golden zone" – the area between your waist and chest – where you should place your most frequently used tools. This zone allows for comfortable access, reducing fatigue and strain.

Insufficient Storage Solutions

Optimizing your tool placement is only half the battle; inadequate storage solutions can quickly turn your garage workshop into a cluttered nightmare.

You'll be surprised how quickly clutter can accumulate, making it difficult to find what you need and creating tripping hazards. Insufficient storage solutions can also lead to damaged tools and equipment.

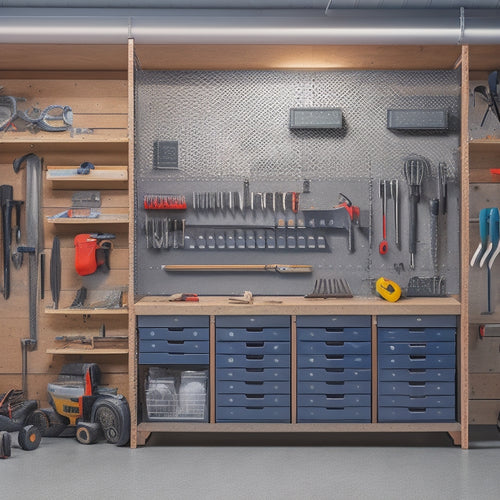

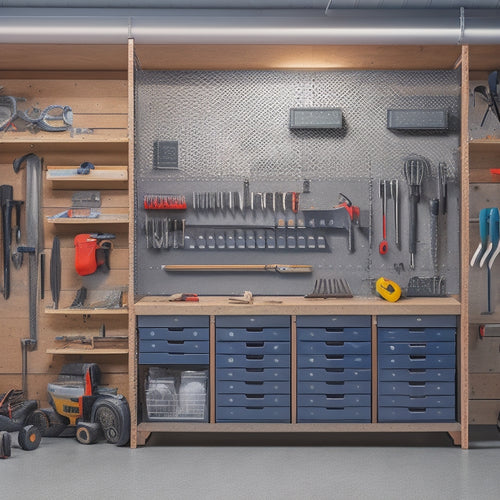

To avoid this, you need a well-planned storage strategy. Consider vertical storage solutions, such as wall-mounted shelves or cabinets, to maximize your garage's vertical space.

Modular shelving units are also a great option, as they can be easily customized to fit your specific needs. Label each storage unit clearly, so you can quickly identify what's inside.

Store items you don't use frequently, like seasonal decorations or out-of-season sports equipment, in labeled bins or containers.

Inefficient Work Flow Design

How do you expect to get any work done efficiently if you're constantly walking around obstacles or searching for tools? A well-designed workshop layout should prioritize workflow efficiency, guaranteeing that you can move freely and access tools quickly.

To achieve this, consider implementing workspace zoning. Divide your garage into dedicated areas for specific tasks, such as a woodworking zone, a metalworking zone, and a tool storage zone. This will help you stay focused on the task at hand and reduce the likelihood of accidents.

| Zone | Tool Accessibility | Workflow Considerations |

|---|---|---|

| Woodworking | Store frequently used woodworking tools, such as saws and sanders, within easy reach. | Designate a specific area for wood preparation and cutting to minimize dust and debris spread. |

| Metalworking | Position metalworking tools, like drill presses and grinders, near a metalworking bench. | Guarantee a metalworking zone is well-ventilated and equipped with fire-resistant materials. |

| Tool Storage | Designate a specific area for less frequently used tools and materials. | Organize tools by category and label storage bins for quick identification. |

Ignoring Ergonomic Considerations

By organizing your workspace into dedicated zones, you've taken a significant step towards maximizing efficiency. However, if you neglect ergonomic considerations, you may still find yourself struggling with discomfort and reduced productivity. Ignoring ergonomic considerations can lead to fatigue, injury, and decreased performance.

When designing your garage workshop layout, prioritize tool accessibility and workstation comfort. Make certain that frequently used tools are within easy reach, reducing the need for excessive stretching or bending.

Position your workstations at comfortable heights, allowing you to work without straining your back or shoulders. Consider investing in adjustable workbenches or stools to accommodate different tasks and users.

Additionally, consider the layout of your workspace in relation to your body. Avoid placing heavy machinery or equipment in areas that require you to twist or turn excessively.

Overcrowding the Work Area

As you're setting up your garage workshop, it's easy to get carried away with the excitement of having all your tools and equipment within arm's reach.

However, this enthusiasm can quickly lead to overcrowding the work area, which can hinder your productivity and compromise your safety.

Overcrowding makes it difficult to move around, increasing the risk of tripping, slipping, or bumping into things. It also leads to clutter management nightmares, making it challenging to find what you need when you need it.

To avoid this mistake, remember:

-

Designate a home for each tool: Assign a specific place for each tool and equipment to prevent clutter from building up.

-

Prioritize workbench organization: Keep your workbench clear of unnecessary items, and organize your tools and materials in a way that makes sense for your workflow.

-

Leave space to breathe: Ascertain there's enough clearance around your work area to move comfortably and safely.

Disregarding Safety Precautions

Five common garage workshop hazards - electrical shock, fire, falling objects, sharp tools, and toxic chemicals - can turn your DIY haven into a dangerous zone if you disregard safety precautions. You might think you're saving time or effort, but the consequences can be severe.

You must prioritize safety gear, such as gloves, safety glasses, and a dust mask, to protect yourself from harm. Make certain you have a well-stocked first-aid kit on hand in case of accidents. Emergency exits should be clearly marked and easily accessible to prevent panic in case of an emergency.

Take the time to inspect your workshop regularly, identifying potential hazards and taking steps to mitigate them. Store flammable liquids and chemicals in well-ventilated areas, away from heat sources.

Keep your workshop tidy, and avoid overloading outlets or using damaged cords. By taking these simple precautions, you can minimize the risk of accidents and create a safe, productive workspace.

Failure to Plan for Expansion

You've invested time and money in your garage workshop, but have you considered what'll happen when you need to add new tools or equipment?

Failure to plan for expansion can lead to a cluttered and inefficient workspace. A future-proof design is essential to accommodate your growing needs.

To avoid this mistake, consider the following:

-

Modular equipment: Invest in equipment that can be easily rearranged or expanded, such as modular workbenches or shelving units.

-

Flexible storage: Plan for storage solutions that can adapt to changing needs, like adjustable shelving or cabinets with removable dividers.

-

Accessible wiring: Guarantee that electrical outlets and wiring are easily accessible, making it simpler to add new tools or equipment in the future.

Frequently Asked Questions

What Is the Ideal Height for a Workbench to Accommodate Different Users?

You'll want a workbench that accommodates different users comfortably, so aim for an adjustable height between 29 and 38 inches to guarantee ideal workbench ergonomics and user comfort, allowing you to work safely and efficiently.

How Can I Maximize Corner Space in My Garage Workshop?

You'll maximize corner space by installing corner shelving and implementing a tool organization system, keeping frequently used items within easy reach while maintaining a safe and efficient workshop environment.

Can I Use a Murphy Table to Save Floor Space?

You're contemplating a Murphy table to conserve floor space; it's a fantastic idea! You'll reap Murphy table benefits like increased clearance and flexibility. Investigate folding table options, guaranteeing stability and secure locking mechanisms to prevent accidents and guarantee a safe workshop environment.

What Type of Flooring Is Best for a Garage Workshop?

You're wise to contemplate flooring options, since a Murphy table can be a tripping hazard. For your garage workshop, choose epoxy flooring or rubber mats for durability and slip resistance, and don't forget concrete sealing and drainage solutions for a safe and functional space.

Can I Convert an Existing Garage Cabinet Into a Workstation?

You can repurpose an existing garage cabinet into a workstation, but consider the cabinet's original purpose and adjust its organization to prioritize workspace efficiency, ensuring a safe and functional area for your projects.

Conclusion

You've made it this far, and now you're ready to create your dream garage workshop! Remember, a well-planned layout is key to maximizing productivity and minimizing frustration. According to a study, 75% of DIYers regret not planning their workshop layout before starting a project. Don't be one of them! By avoiding these common mistakes, you'll be well on your way to creating a space that's both functional and enjoyable.

Related Posts

-

Building a Wall Tool Storage System

You're about to create a customized wall tool storage system that streamlines your workflow. Start by clearing your w...

-

Key Features of a Garage Wall Hanging System

You're looking for a garage wall hanging system that's built to last and adapts to your needs. Look for systems made ...

-

Garage Wall Storage Ideas to Boost Productivity

You can enhance your garage's productivity by capitalizing on your ceiling height with overhead racks, storing bulky ...