Rolling Tool Cases for Efficient Workshop Organization

Share

You're wasting precious time and compromising safety in your workshop by not having an efficient tool storage system. Cluttered spaces and misplaced tools can lead to accidents, lost productivity, and increased frustration. Investing in a rolling tool case can enhance workshop organization and productivity by reducing time spent searching for tools, minimizing risks of accidents, and providing mobility for easy transport. When selecting a case, consider the material, storage compartment design, and size to fit your tool capacity needs and workspace constraints. By doing so, you'll be well on your way to creating a more efficient and organized workshop - and that's just the starting point.

Key Takeaways

- Rolling tool cases enhance workshop organization and productivity by reducing search time and minimizing accidents caused by clutter.

- Material options like plastic, metal, fabric, and composite impact durability, weight, and waterproofing, and should be prioritized based on usage and conditions.

- Storage compartment design affects accessibility and organization, with separate compartments for different tool types, snug fits, and well-organized layouts reducing frustration.

- Size considerations should evaluate tool capacity needs, workspace constraints, and vehicle clearance to ensure a comfortable fit and easy maneuverability.

- Customizing tool storage with labels, modular inserts, color coding, and tool silhouettes can further enhance tool accessibility and convenience.

Benefits of Rolling Tool Cases

Several rolling tool cases can make a significant difference in your workshop's organization and productivity. By having multiple cases, you can categorize and store your tools in a way that makes sense for your workflow, ensuring that everything has its designated place.

This, in turn, reduces the time spent searching for misplaced tools and minimizes the risk of accidents caused by clutter.

One of the significant tool case advantages is the mobility benefits they provide. Rolling cases allow you to easily transport your tools to different areas of the workshop or even to different job sites.

This mobility is especially important when working on large projects that require multiple tools and equipment. With a rolling tool case, you can quickly move your tools to where they're needed, saving time and energy.

Key Features to Consider

When selecting a rolling tool case, you'll want to contemplate the case material options, as they can impact durability and weight.

You'll also want to think about the storage compartment design, as it affects how easily you can access and organize your tools.

Case Material Options

Your rolling tool case's material is its backbone, providing the strength and durability you need to haul your gear around the workshop. When choosing a rolling tool case, you'll come across various material options, each with its pros and cons.

Here's a breakdown of popular case material options:

| Material | Durability | Weight | Waterproof |

|---|---|---|---|

| Plastic | Good | Light | Yes |

| Metal | Excellent | Heavy | Yes |

| Fabric | Fair | Light | No |

| Composite | Excellent | Medium | Yes |

Consider your priorities: do you need a case that's lightweight and easy to maneuver, or one that's ultra-durable and can withstand heavy use? If you work in wet or humid conditions, look for waterproof options. Eco-friendly materials and insulation properties may also be important to you. Finally, think about maintenance tips and color choices that fit your workshop style. By assessing these factors, you'll find the perfect case material for your needs.

Storage Compartment Design

Now that you've chosen the perfect material for your rolling tool case, it's time to think about how you'll organize your tools inside. A well-designed storage compartment is essential for efficient workshop organization. You want to guarantee that your tools are easily accessible and protected from damage.

When considering storage compartment design, think about compartment functionality and compartment accessibility. You'll want to create separate compartments for different types of tools and supplies, such as:

- Small parts and screws

- Hand tools like wrenches and pliers

- Power tools like drills and saws

This will help you quickly find what you need and prevent tools from getting lost or damaged.

Additionally, consider the size and shape of your tools when designing the compartments. You'll want to confirm that each tool fits snugly in its designated space, and that you can easily retrieve it when needed.

A well-organized storage compartment will save you time and reduce frustration in the workshop.

Choosing the Right Size

When choosing a rolling tool case, you'll need to evaluate the case's size, your tool capacity needs, and the space available in your workshop.

You'll want to ponder the types and quantities of tools you need to store and transport, as well as the floor space and shelving you have available.

Case Size Considerations

Frequently, the most overlooked aspect of selecting a rolling tool case is the case size, which ultimately determines how efficiently you can store and transport your tools.

You'll want to evaluate the case dimensions to ascertain it fits comfortably in your workshop or vehicle. A case that's too large may be cumbersome, while one that's too small may not hold all your essential tools.

When assessing case size, keep the following factors in mind:

-

Case weight: A heavier case may be more durable, but it can also be more difficult to maneuver, especially if you need to transport it up stairs or over long distances.

-

Workspace constraints: Measure your workshop or storage area to confirm the case fits comfortably and leaves enough room to move around it.

-

Portability needs: If you plan to transport your tools to different job sites, evaluate a case with compact dimensions and a manageable weight.

Tool Capacity Needs

Your tool collection's diversity and quantity greatly influence the ideal rolling tool case size. You need to evaluate the types of tools you have, their weight, and how often you use them.

For instance, if you have a lot of heavy power tools, you'll need a larger case with sturdy wheels to support the weight. On the other hand, if you have a collection of lighter hand tools, a smaller case might suffice.

Reflect on the tool types you use most frequently and how you want to organize them. Do you have a lot of long, thin tools like screwdrivers and wrenches? You'll need a case with compartments that can accommodate their length.

Are you a woodworker with a lot of bulky equipment? You might need a larger case with compartments that can hold your sanders, drills, and saws.

Space Availability Assessment

With the tool capacity needs in mind, it's essential to assess the space where you plan to store and transport your rolling tool case. You need to take into account the workshop layout, workspace dimensions, and available space to guarantee a smooth and efficient operation.

Take inventory of the available space in your workshop by measuring the width, length, and height of the areas where you plan to store and use the rolling tool case. Reflect on the following factors:

-

Workspace constraints: Measure the distance between workbenches, shelving, and other obstacles to ascertain the rolling tool case fits comfortably.

-

Doorway and hallway clearance: Measure the width of doorways and hallways to make sure the case can be easily transported.

-

Storage space dimensions: Measure the dimensions of the storage area to confirm the case fits snugly and can be easily accessed.

Customizing Your Tool Storage

You're not limited to the tool storage options that come with your rolling tool case. You can customize your storage to fit your specific needs and workflow.

Start by adding custom labels to identify what's inside each drawer or compartment. This will save you time and reduce frustration when searching for a specific tool.

Modular inserts and drawer dividers can help keep similar tools organized and prevent clutter. Color coding can also be an effective way to categorize tools by type or project.

Consider adding tool trays with magnetic strips to store small metal tools, or foam padding to protect delicate items. Create a tool silhouette to outline the shape of each tool, making it easy to identify where each one belongs.

Don't forget to add ergonomic handles to make it comfortable to carry your case, and locking mechanisms to secure your precious tools.

Maximizing Vertical Space

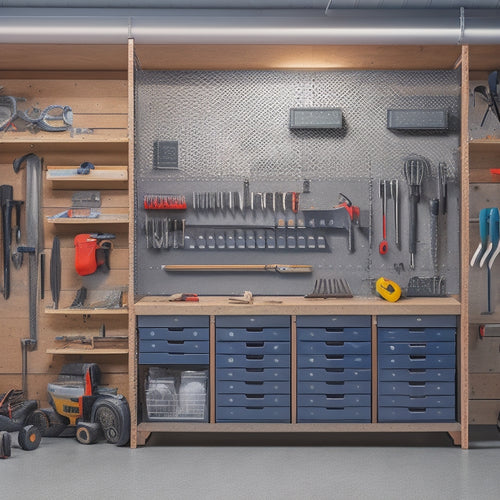

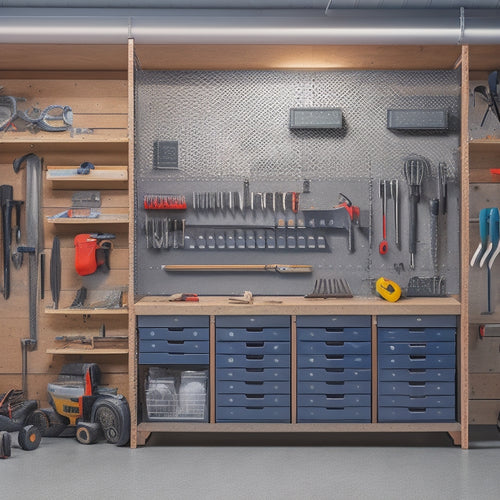

Customization sets the stage for ideal tool storage, and now it's time to take it to new heights - literally. Maximizing vertical space is essential in workshops where every square foot counts. By utilizing wall-mounted storage and vertical shelving, you can free up floor space and reduce clutter.

Here are some ways to make the most of your workshop's vertical space:

-

Install wall-mounted pegboards to hang frequently used tools and accessories, keeping them within easy reach.

-

Invest in vertical shelving units that can store larger items like power tools, bins, and containers.

-

Consider using stackable storage bins and baskets to store smaller items like nuts, bolts, and other hardware.

Organization Ideas for Drawers

Optimizing your workshop's drawers is crucial for swift tool retrieval and minimizing downtime. You can achieve this by implementing a few simple yet effective organization ideas.

Start by installing drawer dividers to separate tools into categories, making it easier to find what you need quickly. Label each divider to guarantee you can identify the contents at a glance. This will prevent you from wasting time searching for a specific tool.

Next, organize your tools within each divider using a logical system. For example, you can group similar tools together, such as all your screwdrivers or pliers.

Consider using inserts or small trays to store small items like nuts, bolts, or screws. This will keep them from getting lost or damaged.

Tool Accessibility and Convenience

A well-organized workshop relies on easy access to tools, which saves time and enhances productivity. When you can quickly locate the tool you need, you can complete tasks more efficiently and reduce downtime. This is where a rolling tool case comes in handy.

With a rolling tool case, you can store your tools in a centralized location, making them easily accessible whenever you need them. This improves tool retrieval and reduces the risk of misplacing or losing tools.

Here are some benefits of using a rolling tool case for tool accessibility and convenience:

-

Reduced walking distance: With a rolling tool case, you can keep your tools close to your workspace, reducing the need to walk back and forth to retrieve them.

-

Improved workspace efficiency: By keeping your tools organized and within reach, you can focus on your work without interruptions, increasing your productivity and efficiency.

-

Enhanced safety: A rolling tool case helps prevent tripping hazards and reduces the risk of accidents caused by scattered tools.

Durability and Portability Matters

As you're constantly on the move between projects, you need a rolling tool case that can keep up with your pace. Durability and portability are essential factors to take into account when choosing the right tool case for your workshop. A sturdy tool case with strong material strength can withstand the rigors of frequent transportation and harsh workshop conditions.

When evaluating a rolling tool case, look for the following features:

| Feature | Importance |

|---|---|

| Material Strength | High |

| Weight Distribution | High |

| Wheels and Handles | Medium |

A tool case with a sturdy frame and reinforced corners can protect your important tools from damage. Even weight distribution guarantees that the case remains stable and balanced, reducing the risk of accidents. While wheels and handles are significant for ease of movement, they shouldn't compromise the overall durability of the case. By prioritizing these features, you can verify that your rolling tool case remains a reliable and safe companion in your workshop.

Upgrading Your Workshop Productivity

Three key areas in your workshop can be markedly improved with a well-designed rolling tool case: tool accessibility, workspace efficiency, and productivity.

By optimizing your tool storage and organization, you can streamline your workflow, reduce downtime, and increase your overall productivity.

With a rolling tool case, you can:

-

Simplify task prioritization: Quickly identify and access the tools you need for a specific task, allowing you to focus on the job at hand.

-

Enhance workflow optimization: Organize your tools in a logical and sequential manner, reducing the time spent searching for misplaced items and increasing your efficiency.

-

Increase safety: Keep your workspace clear of clutter and tripping hazards, reducing the risk of accidents and injuries.

Frequently Asked Questions

Can Rolling Tool Cases Be Used on Uneven or Rough Workshop Floors?

You'll be glad to know that most rolling tool cases can handle uneven or rough floors, but it's essential to check the wheel performance and floor stability to guarantee smooth movement and prevent accidents or damage.

Are Rolling Tool Cases Suitable for Outdoor or Job Site Use?

Will you really be able to get the job done if your tools aren't protected from the elements? You'll want a rolling tool case with weather resistance and thoughtful portability features, like sturdy wheels and reinforced handles, to guarantee your gear stays safe and organized on outdoor job sites.

Can I Lock My Rolling Tool Case to Prevent Theft or Tampering?

You can take tool security to the next level by investing in a lockable rolling tool case, ensuring theft prevention and protecting your precious tools from potential thieves or unauthorized access.

How Often Should I Clean and Maintain My Rolling Tool Case?

You're probably thinking, 'I'm a pro of mess,' but surprise, you're not! Clean your rolling tool case regularly to prevent dirt and grime buildup. Aim for weekly wipes and monthly deep cleans to keep your tools in top shape and your workshop safe.

Are Rolling Tool Cases Compatible With All Types of Tool Sets and Brands?

You'll find that most rolling tool cases are designed to accommodate various tool sets and brands, guaranteeing brand compatibility and efficient tool organization, but it's crucial to check the case's specifications before purchasing to verify a seamless fit.

Conclusion

With a rolling tool case, you'll be unstoppable! Your workshop will change into a productivity powerhouse, where every second counts and every tool is at your fingertips. You'll be a guru of efficiency, completing projects in record time and leaving your competition in the dust. Don't settle for a cluttered, chaotic workspace – upgrade to a rolling tool case and experience the thrill of getting more done in less time!

Related Posts

-

Building a Wall Tool Storage System

You're about to create a customized wall tool storage system that streamlines your workflow. Start by clearing your w...

-

Choosing the Right Stacked Storage Bins

When choosing the right stacked storage bins, you'll want to evaluate your storage needs, considering inventory types...

-

Best Cheap Tool Boxes for Budget-Conscious Buyers

You need a reliable tool box that gets the job done without breaking the bank. Look for durable materials, rust-resis...