Customize Your Small Shop With Tool Storage Solutions

Share

You're likely wasting valuable time and floor space in your small shop due to inefficient tool storage, but with a customized system, you can enhance your layout, streamline your workflow, and boost productivity. Start by identifying areas needing efficient tool storage solutions, considering your shop goals, and prioritizing storage solutions based on your needs. Maximize vertical storage space by installing ceiling hooks and corner shelves, and develop an ideal tool organization strategy with clear labeling and signage. By implementing these solutions, you'll be able to create a clutter-free environment that enhances your productivity - and that's just the beginning of reaching your shop's full potential.

Key Takeaways

• Assess your small shop's needs by identifying areas for efficient tool storage, frequently used tools, and shop goals to increase productivity or free up floor space.

• Maximize vertical storage space by utilizing underused areas, installing ceiling hooks, and mounting corner shelves to increase storage capacity.

• Develop efficient tool organization strategies by grouping tools into functional categories, using clear labeling, and maximizing storage space with a floor map.

• Customize your pegboard layout to maximize storage capacity and efficiency, considering aesthetics and functionality in the design.

• Implement a tool storage system that allocates tools effectively, stores less frequently used tools separately, and uses clear labels and dividers for quick tool identification.

Assessing Your Small Shop Needs

Determine how you currently use your small shop space to identify areas that require more efficient tool storage solutions. Take note of the tools you use frequently and those that are collecting dust. Consider your shop goals: what do you want to achieve in your workspace? Do you want to increase productivity, reduce clutter, or free up floor space? Understanding your needs will help you prioritize your tool storage solutions.

Next, assess your space constraints. Measure your shop's dimensions, including any obstacles like pillars or windows. Identify the areas where you can install tool storage solutions, such as walls, corners, or countertops.

Consider the height and width of your tools and equipment to determine the most suitable storage options.

Maximizing Vertical Storage Space

By leveraging your shop's often-underutilized vertical space, you can greatly increase storage capacity without sacrificing valuable floor real estate. This is especially vital in small shops where every square foot counts.

One effective way to maximize vertical storage is by installing ceiling hooks. These can hold bicycles, tools, or even bins, keeping them off the floor and out of the way.

Additionally, consider corner shelves that can be mounted high up on walls, perfect for storing less frequently used items like seasonal decorations or infrequently used tools. These shelves are great for making the most of the often-wasted space in corners.

When choosing your storage solutions, make sure to take into account the weight capacity and durability of the materials. You want to make certain that your storage systems can support the weight of your items and withstand the wear and tear of daily use.

Optimal Tool Organization Strategies

As you set up your tool storage system, it's crucial to develop efficient tool organization strategies to make sure you can quickly find what you need when you need it.

You'll want to group your tools in a way that makes sense for your workflow, maximize your storage space, and use clear labeling and signage to help you identify where everything is.

Tool Grouping Methods

You can optimize your tool organization by categorizing tools into functional groups, such as handheld tools, power tools, and measuring instruments, in order to facilitate quick access and efficient workflow. This approach enables you to locate the tools you need when you need them, saving time and reducing frustration.

Here are some effective tool grouping methods worth exploring:

-

Tool Clusters: Group tools that are often used together, such as a drill and bits, or a wrench and socket set.

-

Category Blocks: Organize tools by category, like all cutting tools or all fastening tools, to create a logical and easy-to-follow system.

-

Frequency-Based Groups: Store your most frequently used tools in an easily accessible area, and less frequently used tools in a secondary location.

Storage Space Maximization

With your tools grouped into functional categories, it's time to maximize your storage space by implementing efficient tool organization strategies that make the most of your shop's layout.

You'll want to focus on corner utilization, as these areas often go unused. Consider installing corner shelves, cabinets, or carousels to store items like drill bits, sandpaper, or other small accessories.

Next, create a floor map to visualize your shop's layout and identify areas where you can optimize storage. Identify high-traffic zones and position your most frequently used tools in easy-to-reach locations. This will save you time and energy in the long run.

Think vertically, too, by installing wall-mounted pegboards, hooks, or bins to store items like hammers, screwdrivers, or cleaning supplies.

By making the most of your shop's layout, you'll be able to fit more tools into a smaller space, increasing your productivity and reducing frustration.

With these strategies, you'll be well on your way to a more efficient and organized workshop.

Labeling and Signage

By assigning a clear label to each storage bin, shelf, and pegboard, you'll create a visual system that instantly tells you where to find the tool you need. This labeling system will save you time and reduce frustration when searching for a specific tool.

To make your labels stand out, consider using bright and contrasting label colors that catch your attention.

Here are some essential considerations for effective labeling and signage:

-

Choose durable signage materials that can withstand the workshop environment, such as vinyl or polyester labels, and metal or plastic signs.

-

Keep labels concise and clear, using simple language and avoiding clutter. This will make sure that you can quickly identify the contents of each storage bin or shelf.

-

Use a consistent labeling format throughout your workshop, making it easy to navigate and find what you need.

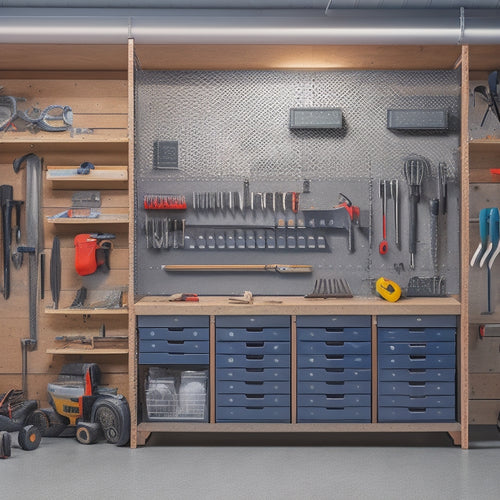

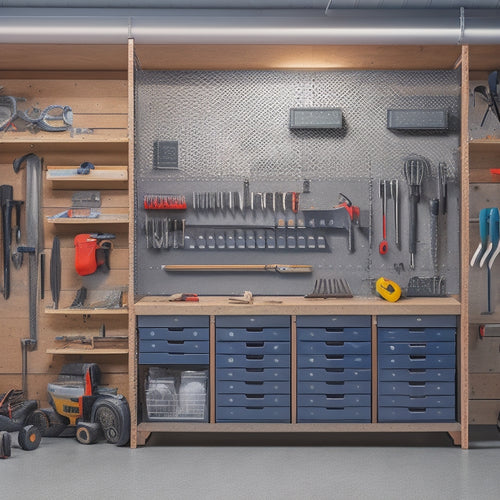

Customizing Your Pegboard Layout

Customizing your pegboard layout requires a thoughtful approach to maximize storage capacity and efficiency in your small shop. You'll want to contemplate both form and function when designing your pegboard layout.

Think about the pegboard aesthetics - do you prefer a symmetrical or asymmetrical layout? Do you want to create a focal point with a central tool or leave some space for visual breathing room?

When it comes to personalized configuration, ponder your workflow and the tools you use most frequently. Place your most-used tools in easy-to-reach locations, and group similar tools together for convenience. Consider the weight and size of your tools, too - you don't want your pegboard to become cluttered or unstable.

Utilizing Mobile Tool Storage

When you're working in a small shop, every inch counts, and that's where mobile tool storage comes in.

You'll want to contemplate a tool cart that's organized to maximize efficiency, as well as portable storage options that can be easily moved around the workspace.

Tool Cart Organization

You can maximize your small shop's efficiency by outfitting your tool cart with a thoughtfully designed storage system that keeps essential tools and supplies within easy reach. This means you'll spend less time searching for what you need and more time getting the job done.

Here are some key considerations to keep in mind:

-

Cart Maintenance: Regularly clean and lubricate your tool cart's wheels to guarantee smooth movement and prevent damage to the floor.

-

Wheel Selection: Choose wheels that are suitable for your shop's floor type, such as soft rubber for hardwood or epoxy-coated concrete, or hard rubber for rough surfaces.

-

Easy-Access Storage: Designate specific areas of the cart for frequently used tools and supplies, and use dividers or bins to keep items organized and easy to find.

Portable Storage Options

By incorporating portable storage options into your small shop, you can further optimize your workspace by bringing the tools and supplies you need directly to the project site. This means you'll spend less time walking back and forth to your tool cart or searching for misplaced items, and more time focused on the task at hand.

Portable storage solutions, such as travel cases and mobile tool chests, allow you to transport your essential tools and supplies to the job site with ease. These compact and versatile storage options can be easily wheeled or carried to the work area, providing you with instant access to the tools you need.

With portable storage, you can work more efficiently, reduce downtime, and increase productivity. Plus, they're perfect for small shops with limited space, as they can be easily stowed away when not in use. By investing in portable storage options, you'll be able to tackle projects with confidence, knowing that your tools and supplies are always within reach.

Space-Saving Designs

Opting for space-saving designs that incorporate mobile tool storage solutions enables small shop owners to maximize their available space without sacrificing tool accessibility. This approach allows you to make the most of your shop's limited area, ensuring that every inch is utilized efficiently. By investing in compact shelves and foldable workstations, you can create a more organized and clutter-free environment that promotes productivity.

Here are some benefits you can expect from space-saving designs:

-

Easy rearrangement: Mobile tool storage solutions can be easily moved or rearranged to accommodate changing project requirements or workflows.

-

Increased visibility: Compact shelves and foldable workstations keep your tools and equipment within easy sight, reducing the time spent searching for them.

-

Improved safety: A clutter-free workspace minimizes tripping hazards and reduces the risk of accidents, creating a safer working environment for you and your team.

Efficient Workbench Storage Ideas

Six essential storage components can be integrated into your workbench to maximize space and streamline your workflow. You'll love how these clever solutions keep your tools and materials within easy reach, freeing up valuable floor space for more important things.

Start by installing bench dividers to separate your work surface into distinct zones. This helps prevent clutter from building up and keeps your projects organized.

Next, utilize corner organizers to make the most of those often-wasted spaces. These clever units can hold everything from power tools to hardware, keeping them neatly tucked away yet still accessible.

Consider adding a pegboard for hanging frequently used items, a tool tray for small parts, and a shelf for storing larger equipment. You can even incorporate a built-in vice or a small parts organizer to really optimize your workbench's functionality.

Creating a Tool Storage System

To create a tool storage system that truly serves your small shop, you'll need to assess your specific needs and categorize your tools into groups based on frequency of use, size, and type. This will help you determine the most effective way to allocate your tools and create a system that's tailored to your unique needs.

Here are three key considerations to keep in mind when creating your tool storage system:

-

Tool Allocation: Think about which tools you use most frequently and make sure they're easily accessible. Store less frequently used tools in a separate area to avoid clutter.

-

Storage Psychology: Consider the mental flow of your work process. Store tools in a way that makes sense to your workflow, so you can quickly find what you need without breaking your concentration.

-

Visual Organization: Use clear labels and dividers to create a visual system that helps you quickly identify where each tool is stored.

Boosting Productivity With Labels

Boosting Productivity With Labels

By assigning a designated home to each tool with clear and descriptive labels, you can shave precious minutes off your workflow and focus on the task at hand. This simple yet effective strategy is rooted in labeling psychology, which suggests that our brains process visual cues more efficiently than text.

With labeled tools, you can quickly identify what you need, reducing the time spent searching and increasing your overall productivity.

To take labeling to the next level, consider implementing a color-coding system. Assign specific colors to different tool categories, such as blue for hand tools or red for power tools. This visual distinction will help you locate tools even faster and prevent mistakes.

Additionally, use labels with clear, concise descriptions to avoid confusion. For example, instead of labeling a bin 'Miscellaneous,' use 'Fasteners and Fixings' to make sure you know exactly what's inside.

Frequently Asked Questions

Can I Use Tool Storage Solutions for a Home Office or Craft Room?

You can totally repurpose tool storage solutions for your home office or craft room! Maximize your desk organization with clever storage bins and create a creative layout that sparks productivity and inspires your best work.

How Do I Protect My Tools From Rust and Corrosion in Storage?

You take precautions to shield your tools from rust and corrosion by controlling humidity levels, using rust inhibitors, and storing them in airtight containers - ensuring your investment stays protected and functional.

Are There Tool Storage Solutions for Very Small or Odd-Shaped Tools?

You'll find perfect fits for those tiny, oddly-shaped tools in micro toolboxes or adaptive organizers with customizable compartments, ensuring they're protected and easy to access, even in cramped spaces.

Can I DIY My Own Tool Storage Solutions or Should I Buy Pre-Made?

"Did you know 60% of DIYers prefer customizing their own storage solutions? You can DIY your own tool storage solutions, but consider your budget constraints and time commitment; if you're short on time, buying pre-made might be the way to go."

How Often Should I Reorganize and Clean My Tool Storage System?

You'll want to reorganize and clean your tool storage system regularly, ideally during seasonal purges, to guarantee everything remains accessible and functional. Create a maintenance schedule to stay on track and make adjustments as needed.

Related Posts

-

Building a Wall Tool Storage System

You're about to create a customized wall tool storage system that streamlines your workflow. Start by clearing your w...

-

Best Materials for Garage Wall-Mounted Cabinets

When selecting materials for your garage wall-mounted cabinets, you'll want to evaluate options that balance durabili...

-

What Are the Advantages of a Wooden Tool Box

You choose a wooden tool box, you're not only getting a reliable storage solution, but also a long list of benefits t...