7 Essential Garage Workshop Design Tips

Share

You're transforming your garage into a workshop that boosts productivity and efficiency. Start by defining your space, considering dimensions, door orientation, and obstructions. Then, choose the right flooring material, prioritizing safety and practicality. Optimize your workbench layout for comfort and efficiency. Create task-oriented zones, each equipped with necessary tools and storage. Select an ideal lighting system, incorporating natural and artificial sources. Utilize vertical storage options, maximizing capacity and minimizing clutter. Finally, plan for electrical outlets, positioning them for easy access and safety. Now, get ready to bring your vision to life with a space that's both functional and safe.

Key Takeaways

• Define your garage workshop space by evaluating dimensions, door orientation, and obstructions to create a logical work path and ideal layout.

• Choose the right flooring material, prioritizing safety, practicality, and durability, with options like epoxy coatings and textured concrete for slip-resistance.

• Optimize your workbench layout by considering ergonomic aspects like height and surface material, and strategically organizing tools for efficiency.

• Incorporate task-oriented zones for woodworking, metalworking, and automotive projects, with necessary tools and storage to increase workflow efficiency.

• Select the ideal lighting system, considering natural and artificial light sources, with bulbs that provide ample illumination and proper task-oriented lighting.

Define Your Garage Workshop Space

Begin by evaluating your garage's dimensions, door orientation, and any obstructions, such as plumbing or electrical fixtures, to determine the best layout for your workshop space. This will help you identify the most vital use of space and potential bottlenecks. Take note of the location of windows, doors, and any existing shelving or cabinets.

Consider how you'll be using your workshop – will you need dedicated areas for specific tasks or projects? Think about the flow of your space and how you can create a logical work path.

Effective space planning is essential in a garage workshop, where every square foot counts. Set boundaries for different areas of your workshop, such as a dedicated zone for tools, a workbench, or a storage area. This will help maintain organization and reduce clutter. By defining your space, you'll be able to work more efficiently and stay focused on your projects.

Take your time to plan and visualize your ideal workshop layout – it'll pay off in the long run.

Choose the Right Flooring Material

When choosing the right flooring material for your garage workshop, you'll want to prioritize safety and practicality. You'll need a floor that can withstand heavy foot traffic, spills, and machinery, while also providing traction to prevent slips and falls.

Consider flooring options that balance durability and maintenance requirements with slip-resistance features to create a safe and functional workspace.

Slip-Resistant Floor Options

You'll want to prioritize slip-resistant floor options in order to ensure your garage workshop remains a safe and functional space, especially in areas prone to oil spills, water, or other liquids. When selecting a flooring material, take into account the level of traction it provides, as well as its durability and ease of cleaning.

Here are some popular slip-resistant floor options to prioritize:

| Flooring Material | Safety Ratings | Additional Benefits |

|---|---|---|

| Epoxy Floor Coatings | High traction, slip-resistant | Resistant to oil, water, and chemicals; easy to clean |

| Polyurethane Floor Coatings | Moderate traction, slip-resistant | UV-resistant, abrasion-resistant, and easy to clean |

| Textured Concrete | Low to moderate traction, slip-resistant | Durable, low maintenance, and cost-effective |

When evaluating these options, take into consideration factors such as the level of foot traffic, the types of liquids that may be spilled, and the overall aesthetic you want to achieve in your garage workshop. By choosing the right slip-resistant flooring material, you'll create a safe and functional space that meets your needs.

Durability and Maintenance

Choosing a flooring material for your garage workshop that can withstand the demands of your work, from heavy machinery to chemical spills, is essential. It's crucial to find a material that balances durability with maintenance requirements. You'll want a floor that can resist scratches, cracks, and fading, while also being easy to clean and maintain.

When selecting a flooring material, consider the level of weather resistance you need. If you live in an area with high humidity or extreme temperatures, you'll want a material that can withstand these conditions. Epoxy coatings offer excellent weather resistance and can be applied over concrete or other flooring materials.

Additionally, if you work with metal equipment or machinery, rust prevention is a must. Look for flooring materials with rust-inhibiting properties, such as epoxy or polyurethane coatings, to prevent damage to your equipment and the floor itself.

Optimize Your Workbench Layout

When designing your garage workshop, you'll want to optimize your workbench layout to maximize efficiency and comfort.

You'll need to take into account the ergonomic aspects of your workbench, such as the height and surface material, to make sure you can work comfortably for extended periods.

Workbench Ergonomic Considerations

Optimizing your workbench layout involves carefully considering the height, depth, and surface area to create a comfortable and efficient workspace that adapts to your body's needs.

As you design your workbench, think about your body positioning and how you'll be using the space. You want to avoid straining or bending, which can lead to fatigue and discomfort.

When it comes to wrist angles, you'll want to make sure that your work surface is at a comfortable height that allows you to keep your wrists straight. This will help prevent strain and injury. Consider a workbench with a split-level surface or a tilting top to accommodate different tasks and tools. This will also allow you to adjust the height and angle of your work surface to suit your needs.

Additionally, think about the surface area and how you'll be moving around the workbench. You'll want to leave enough room to move freely and comfortably, without feeling cramped or restricted.

Tool Organization Strategies

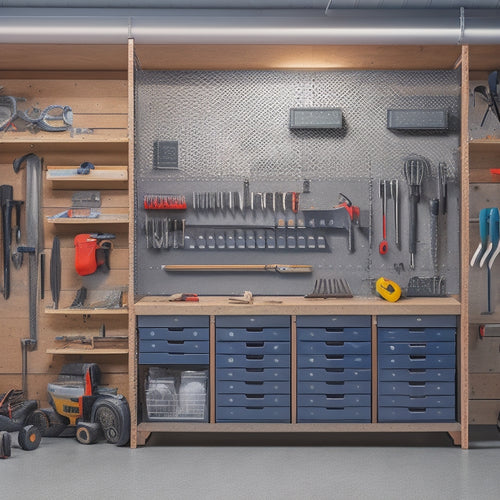

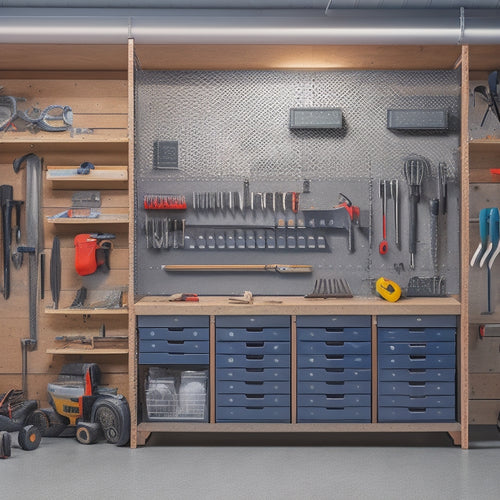

With your ergonomic workbench layout in place, you can now focus on maximizing its potential by strategically organizing your tools to streamline your workflow and reduce downtime. A well-organized workspace is essential to increase productivity and reduce frustration.

To achieve this, consider the concept of 'Tool Shadows.' This refers to designating a specific spot for each tool, making it easy to find and return tools to their designated place. This can be achieved by using Pegboard Panels, which provide a versatile and customizable solution for hanging tools.

Here are some additional tips to optimize your tool organization:

-

Group similar tools together, such as all hand tools or power tools, to reduce searching time.

-

Label each tool's designated spot, making it easy to identify where tools belong.

-

Keep frequently used tools within easy reach, reducing the need to walk around the workshop.

- Store less frequently used tools in labeled bins or containers, keeping them organized and out of the way.

Incorporate Task-Oriented Zones

Designate specific areas within your garage workshop for distinct tasks, like woodworking, metalworking, or automotive projects, to boost efficiency and reduce clutter.

By incorporating task-oriented zones, you'll create a more organized and functional space that streamlines your workflow. Zone segregation is key to achieving this.

For instance, you can dedicate one area for woodworking, complete with a workbench, table saw, and storage for wood and tools. Another zone can be reserved for metalworking, equipped with a metal lathe, drill press, and metal storage bins.

This segregation will prevent tools and materials from getting mixed up, reducing the time spent searching for misplaced items. As a result, your workflow efficiency will increase, allowing you to complete projects faster and with greater accuracy.

Additionally, having designated zones will encourage you to maintain a cleaner and more organized workspace, making it easier to focus on your projects without distractions.

Select the Ideal Lighting System

Selecting the appropriate lighting system for your garage workshop is crucial, as it directly impacts your ability to see details, work safely, and maintain productivity. You'll want to take into account both natural and artificial light sources to create an ideal environment.

When it comes to artificial lighting, take note of the following factors:

-

Color Temperature: Look for bulbs with a color temperature between 3500K and 5000K, which provide a bright, neutral light ideal for task-oriented activities.

-

Lumen Output: Choose bulbs with a high lumen output (around 800-1000 lumens) to ensure ample illumination.

-

Fixture Type: Consider installing overhead lighting, under-cabinet lighting, or task lighting to create a layered lighting effect.

- Dimmer Switches: Install dimmer switches to adjust the lighting levels based on your needs.

Remember to also make use of natural light by placing workstations near windows or installing skylights.

A well-designed lighting system will help you stay focused, avoid eye strain, and enjoy a more comfortable working experience in your garage workshop.

Utilize Vertical Storage Options

To maximize your garage workshop's storage capacity, you'll want to make the most of your ceiling height by incorporating vertical storage options that keep your tools and materials organized and easily accessible.

Overhead racks are a great way to store infrequently used items, such as seasonal decorations or out-of-season sports equipment, freeing up valuable floor space. Consider installing adjustable racks that can be customized to fit your specific storage needs.

For shelved storage, use shelf dividers to separate and categorize your tools and materials. This will prevent clutter from building up and make it easier to find what you need when you need it. Label each shelf and divider to maintain organization and make certain that everything has a designated home.

Plan for Electrical Outlets

As you layout your garage workshop, you'll need to strategically position electrical outlets to make sure they're within easy reach of your workstations and tools, minimizing the risk of tripping hazards and keeping your workflow efficient. This means considering the placement of your workbenches, tool chests, and other equipment to ensure that outlets are easily accessible.

Here are some key considerations for outlet placement:

-

Height: Install outlets at a comfortable height to avoid bending or straining. Typically, this is between 12-18 inches above the floor.

-

Frequency: Place outlets every 4-6 feet to minimize the use of extension cords and reduce tripping hazards.

-

Dedicated circuits: Consider dedicating specific circuits to heavy-duty tools or equipment to prevent overloading and ensure reliable power.

- GFCI protection: Install Ground Fault Circuit Interrupter (GFCI) outlets near water sources, such as sinks or wet work areas, to prevent electrical shock.

Frequently Asked Questions

Can I Convert My Garage Into a Workshop While Keeping My Parking Space?

"You can definitely convert your garage into a workshop while keeping your parking space. Start by space planning to identify dedicated work zones, ensuring a clear path for your vehicle and a functional area for projects."

How Do I Ensure Good Air Quality in a Garage Workshop?

"You'll want to prioritize good air quality in your garage workshop; implement ventilation strategies like installing exhaust fans and vents, and consider adding air purifiers to remove dust and fumes, ensuring a healthier work environment."

Are Epoxy-Coated Floors Suitable for a Garage Workshop?

You'll love epoxy-coated floors in your garage workshop, as they offer excellent floor durability and slip resistance, ensuring a safe and long-lasting surface that can withstand heavy foot traffic and equipment usage.

Can a Garage Workshop Be Soundproofed for Noisy Projects?

You can soundproof your garage workshop for noisy projects by using soundproofing materials like mass-loaded vinyl, acoustic caulk, and spray foam, and incorporating acoustic panels on walls and ceilings to absorb sound waves.

Do I Need a Dust Collection System in My Garage Workshop?

You'll definitely need a dust collection system in your garage workshop to minimize dust hazards and maintain air cleanliness, especially when working with power tools or materials that generate fine particles.

Related Posts

-

Building a Wall Tool Storage System

You're about to create a customized wall tool storage system that streamlines your workflow. Start by clearing your w...

-

10 Essential Steps for Small Parts Bin Storage

To optimize your small parts bin storage, start by defining your storage needs and goals, considering factors like av...

-

Benefits of Pegboard Racks in Your Garage

By installing a pegboard rack in your garage, you'll reveal a wealth of benefits that change your workspace into a hi...