5 Essential Workflow Hacks for Woodworkers

Share

You're likely wasting up to 30% of your woodworking time on inefficient workflows, costing you valuable hours and profits. To optimize your workflow, start by streamlining your workspace setup - declutter, evaluate, and create zones for tasks. Next, categorize and group tools together, and consider a pegboard or slatwall for organization. Master batch processing techniques to reduce setup time and minimize equipment changes. Implement efficient cutting strategies to minimize waste and save time. Finally, identify and eliminate time-wasting tasks to maximize your time management. By implementing these hacks, you'll uncover even more opportunities to supercharge your workflow and take your woodworking to the next level.

Key Takeaways

• Implement an ergonomic workstation to reduce fatigue and discomfort, and optimize tool placement for efficient workflow.

• Organize tools by categorizing, labeling, and designating specific areas to minimize searching time and maximize productivity.

• Master batch processing techniques to optimize efficiency by identifying tasks to batch together, reducing setup time, and minimizing equipment changes.

• Plan cuts in advance, use a story stick, and cut multiple pieces at once to minimize waste, save time, and achieve precision cutting.

• Eliminate time-wasting tasks daily by prioritizing, breaking down larger projects, and implementing the Pomodoro Technique to maintain focus.

Streamline Your Workspace Setup

Optimizing your workspace setup is essential, as a well-organized shop can save you up to 30 minutes of prep time per project. By implementing an ergonomic workstation, you'll reduce fatigue and discomfort, allowing you to focus on the task at hand.

Start by decluttering your workspace using techniques like the 'one touch rule' - put tools and materials away in their designated spot as soon as you're done using them. This will help you avoid wasting time searching for misplaced items.

Next, evaluate your workflow and identify areas where you can implement time-saving layouts. Consider setting up 'zones' for different tasks, such as a cutting zone or a sanding zone, to minimize movement and maximize efficiency.

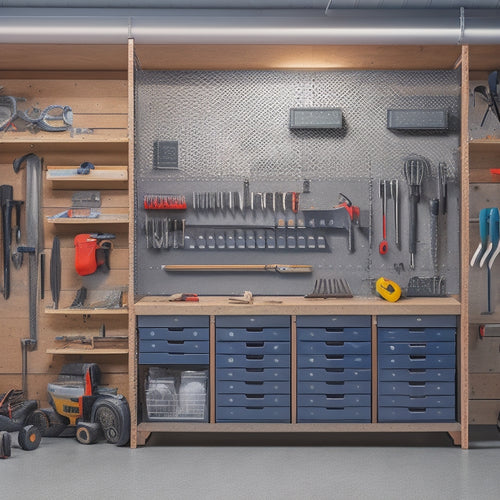

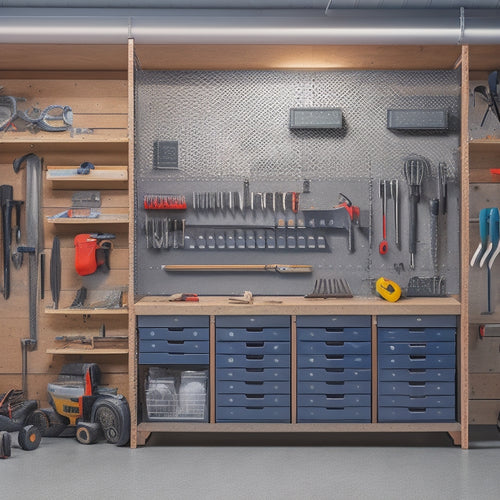

Optimize Tool Organization Systems

By assigning a designated home to each tool, you'll eliminate the frustration of searching for misplaced items and free up valuable time to focus on the creative aspects of your woodworking projects.

A well-organized tool storage system is essential for maximizing your workspace's efficiency. Here are some tips to help you optimize your tool organization:

-

Categorize and group similar tools together, such as all hand saws or power tools, to reduce searching time.

-

Implement a labeling system that clearly identifies each tool's storage location, making it easy to find what you need at a glance.

-

Designate a specific area for frequently used tools, ensuring they're easily accessible and reducing walking distances within your workspace.

- Consider a pegboard or slatwall for hanging tools, keeping them organized and freeing up floor space.

Master Batch Processing Techniques

As you've streamlined your tool organization, you're now ready to tackle the often-daunting task of processing multiple woodworking projects simultaneously, and mastering batch processing techniques will help you make the most of your shop's productivity.

To optimize efficiency, it is crucial to identify tasks that can be batched together. This might include sanding, staining, or assembling similar components. By grouping these tasks, you'll reduce setup time, minimize equipment changes, and optimize your workflow.

Here's a breakdown of batch processing techniques to get you started:

| Task | Batching Strategies |

|---|---|

| Sanding | Sand multiple pieces at once, using a conveyor belt or outfeed table to increase efficiency |

| Staining | Apply stain to multiple pieces simultaneously, using a spray booth or large work surface |

| Assembly | Assemble multiple components in batches, using jigs or fixtures to streamline the process |

| Finishing | Apply finishes in batches, using a controlled environment to minimize dust and debris |

| Quality Control | Inspect and QA multiple pieces at once, using a checklist to guarantee consistency |

Implement Efficient Cutting Strategies

You can greatly reduce cutting time and improve accuracy by developing a strategic approach to cutting, which involves careful planning, clever jig setup, and a few clever tricks up your sleeve. By optimizing your cutting process, you'll be able to achieve precision cutting and make the most of your materials.

Here are some essential tips to get you started:

-

Plan your cuts in advance: Take the time to carefully plan out your cuts, considering the size and shape of the material you're working with. This will help you minimize waste and reduce the number of cuts you need to make.

-

Use a story stick: A story stick is a simple jig that helps you make consistent, accurate cuts. By using a story stick, you can guarantee that all your pieces are cut to the same size and shape.

-

Cut in batches: Cutting multiple pieces at once can save you a significant amount of time and effort. Try cutting all your pieces for a particular project at the same time to optimize your workflow.

- Optimize your material usage: Make the most of your materials by planning your cuts to minimize waste. This won't only save you money but also reduce your environmental impact.

Eliminate Time-Wasting Tasks Daily

Your daily woodworking routine is likely filled with tasks that eat away at your productivity, from tedious sanding to repetitive assembly, and identifying these time-wasting tasks is essential to streamlining your workflow. By pinpointing these tasks, you can eliminate them or find ways to make them more efficient, freeing up more time for high-priority projects.

Effective task prioritization is key to maximizing your time management. Start by identifying the most critical tasks that require your attention and focus on those first. Break down larger projects into smaller, manageable chunks, and allocate specific time slots for each task. This will help you stay on track and avoid procrastination.

To minimize distractions and maintain focus, implement techniques like the Pomodoro Technique, which involves working in 25-minute increments, followed by a five-minute break. This technique can help you stay focused and avoid burnout.

Additionally, consider implementing a 'stop doing' list, where you identify tasks that are no longer necessary or that are taking up too much of your time. By eliminating these tasks and staying focused on high-priority projects, you'll be able to optimize your workflow and achieve more in less time.

Frequently Asked Questions

How Do I Handle Wood Movement During Glue-Up and Assembly?

When you're assembling wood pieces, you'll discover that wood movement is inevitable; to combat this, you're wise to prioritize moisture control and proper clamping to prevent expansion, and reinforce joints for added stability.

What Safety Protocols Should I Follow When Working With Power Tools?

When working with power tools, you must prioritize safety: wear essential safety gear, take necessary precautions, and receive proper training to avoid accidents. Regularly maintain and operate tools correctly to minimize risks.

Can I Use Reclaimed or Salvaged Wood for My Woodworking Projects?

'You're drawn to the rustic charm of reclaimed wood, but will it compromise your project's integrity? By choosing sustainable sourcing, you'll reduce environmental impact, and with careful design considerations, access a unique aesthetic appeal that's both eco-friendly and visually stunning.'

How Do I Achieve Consistent Stain Color Across Different Wood Species?

To achieve consistent stain color, you'll need to verify stain compatibility by testing on each wood species, then prepare the wood properly. Next, use color matching techniques and master various finishing techniques to get the desired result.

What's the Best Way to Dispose of Hazardous Woodworking Waste?

'You're not just sweeping your workshop's hazardous waste under the rug, are you? Proper disposal is key, so research local regulations and recycle whenever possible to guarantee eco-friendly handling of hazardous waste, protecting both you and the environment.'

Related Posts

-

3 Pro Garage Organization Ideas to Try Now

You can alter your garage from cluttered chaos to organized oasis with three pro garage organization ideas. First, op...

-

Building a Wall Tool Storage System

You're about to create a customized wall tool storage system that streamlines your workflow. Start by clearing your w...

-

Heavy-Duty Commercial Rolling Shelving Racks

You need heavy-duty commercial rolling shelving racks that optimize your storage capacity, streamline operations, and...