3 Steps to Create a Custom Tool Chest Table

Share

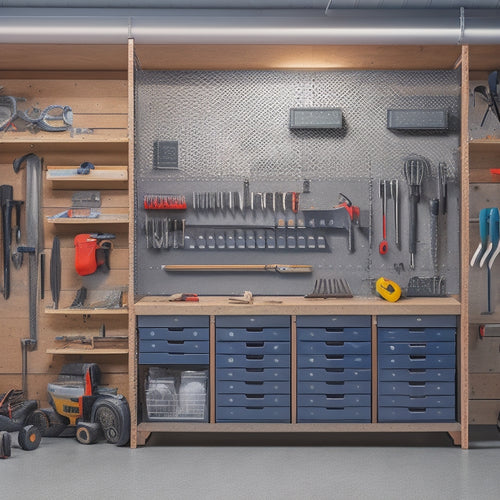

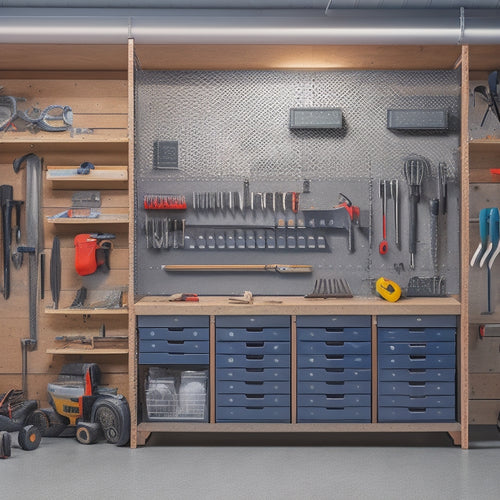

You'll create a highly functional and efficient custom tool chest table by following three straightforward steps. First, plan your design by determining tool types and sizes, deciding on organization methods, and selecting durable materials. Next, build the table and frame simultaneously using heavy-duty tools and reinforced corner brackets for stability. Finally, add drawers and accessories, developing a strategy for organization and incorporating safety features. By following these steps, you'll be well on your way to crafting a custom tool chest table that streamlines your workflow and enhances your productivity.

Key Takeaways

- Determine tool types and sizes to create an optimal layout for your custom tool chest table.

- Choose durable materials, such as wood or metal, and ensure adequate ventilation to prevent moisture buildup.

- Construct a sturdy table and frame simultaneously, using reinforced corner brackets and heavy-duty hinges for stability.

- Develop a drawer organization strategy and select accessories that enhance workflow and organization, such as dividers and tool holders.

- Incorporate safety features, like soft-close drawers and rust-resistant finishes, to create a functional and safe workspace.

Plan Your Tool Chest Design

You're about to commence on an essential phase of your custom tool chest table project: designing the tool chest itself. This is where you'll decide how to organize your tools efficiently, guaranteeing easy access and maximizing storage space.

Consider the types of tools you'll be storing and their sizes to determine the best layout. Think about tool organization: will you use dividers, compartments, or a pegboard? Decide on the material selection for the chest, such as wood, metal, or a combination of both. Verify the material is durable and resistant to corrosion, especially if you'll be storing tools that may be exposed to moisture.

Measure and calculate the interior dimensions of the chest to accommodate your tools. Consider the height, width, and depth of each tool, as well as the space needed for future additions.

Don't forget to plan for adequate ventilation to prevent moisture buildup. A well-designed tool chest won't only keep your tools organized but also protect them from damage and prolong their lifespan.

Build the Table and Frame

Frequently, the table and frame of a custom tool chest are built simultaneously, allowing for a sturdy foundation that can support the weight of the tools and chest.

As you begin building, verify you've made informed material choices, selecting durable materials that can withstand the rigors of daily use. Choose a sturdy wood, such as oak or maple, and pair it with rust-resistant metal hardware.

When selecting tools, prioritize those that can handle the demands of heavy-duty construction. A table saw, miter saw, and drill press will help you make accurate cuts and assemble the frame efficiently. For added stability, consider using reinforced corner brackets and heavy-duty hinges.

As you assemble the frame, focus on creating a square and level foundation. Use clamps to hold the components in place, and double-check your measurements to avoid errors.

Remember to follow safety guidelines, wearing protective gear and maintaining a clean workspace to minimize the risk of accidents.

Add Drawers and Accessories

Your custom tool chest's functionality takes a significant leap forward as you add drawers and accessories. This is where you get to tailor your tool chest to your specific needs, ensuring that every tool has a designated spot. Start by determining your drawer organization strategy. Will you have separate drawers for hand tools, power tools, and fasteners, or will you organize by project type? Once you have a plan, you can begin selecting accessories that complement your workflow.

| Accessory | Purpose |

|---|---|

| Drawer dividers | Keep tools organized and prevent scratching |

| Tool holders | Securely store frequently used tools |

| Fastener organizers | Keep screws, nuts, and bolts tidy |

| Power tool charging stations | Keep your tools charged and ready |

When selecting accessories, prioritize safety and functionality. Consider features like soft-close drawers, rust-resistant finishes, and ergonomic handles. By thoughtfully adding drawers and accessories, you'll create a tool chest that's both efficient and enjoyable to use.

Frequently Asked Questions

How Do I Protect My Tool Chest From Rust and Corrosion?

You'll prevent rust and corrosion by applying a rust-inhibiting coating, storing tools in a dry, well-ventilated area, and using corrosion-resistant materials like stainless steel or galvanized metal for your tool chest's construction.

Can I Add Electrical Outlets to My Tool Chest Table?

You're wise to contemplate adding outlets to your tool chest table, as 70% of DIYers wish they had more power sources nearby. When planning outlet placement, prioritize electrical safety by keeping them away from water sources and ensuring proper wire management and grounding.

What Is the Ideal Height for a Tool Chest Table?

When designing your workspace, you're wise to take into account tool chest ergonomics; for best comfort and safety, you'll want the table's ideal height to be around 36-40 inches, allowing you to stand comfortably while maintaining efficient workspace organization.

How Do I Secure My Tool Chest to the Floor or Wall?

Before disaster strikes, you're wise to anchor your tool chest to the floor or wall, ensuring stability and preventing accidents. You'll find various mounting options, from anti-tip brackets to anchor screws, to secure your tool chest and safeguard your workspace.

Can I Customize My Tool Chest With a Different Finish or Stain?

You can customize your tool chest with a different finish or stain by exploring custom finishes, such as powder coating or ceramic, and stain options like polyurethane, oil-based, or water-based, ensuring a durable and safe finish that meets your workshop needs.

Conclusion

You've managed to create a custom tool chest table that's only slightly less impressive than a professional's. Now, go ahead and pat yourself on the back while simultaneously tripping over the power tools scattered all over your garage floor. As you gaze lovingly at your handiwork, try not to notice the slight wobble in the legs or the wonky drawer that still doesn't quite close right. It's a work of art, really.

Related Posts

-

Building a Wall Tool Storage System

You're about to create a customized wall tool storage system that streamlines your workflow. Start by clearing your w...

-

What Size Rolling Storage Bin Do I Need

To determine the ideal size of your rolling storage bin, you'll need to measure your storage space accurately, consid...

-

Best Cheap Tool Boxes for Budget-Conscious Buyers

You need a reliable tool box that gets the job done without breaking the bank. Look for durable materials, rust-resis...