What Is the Socket Tray Function?

Share

You use socket trays to hold and organize electrical components, ensuring safe connections and efficient power supply in various applications, from data centers to residential buildings, by providing a secure and structured way to manage outlets and cables. They're made of durable materials like plastics or metals and come in different shapes and sizes to accommodate various electrical components. Proper installation and maintenance are essential for safe and reliable operation. By using socket trays, you'll reduce electrical hazards, simplify cable management, and increase productivity - and that's just the beginning of what you'll uncover about these versatile tools.

Key Takeaways

- Socket trays hold and organize electrical components for safe connections, ensuring reliable operation and minimizing electrical hazards.

- They provide a secure and efficient way to manage cables, reducing tangles and potential damage to cables and components.

- Socket trays support multiple socket types, including screw-in, snap-in, and press-fit, to accommodate various electrical components.

- They enhance safety by reducing the risk of accidental contact with live wires, overheating, and electrical fires.

- Socket trays simplify outlet identification and access, increasing productivity and reducing time spent searching for outlets.

Understanding Socket Tray Basics

As clarity takes center stage in the domain of electronics, understanding socket tray basics becomes an important foundation for efficient design and assembly.

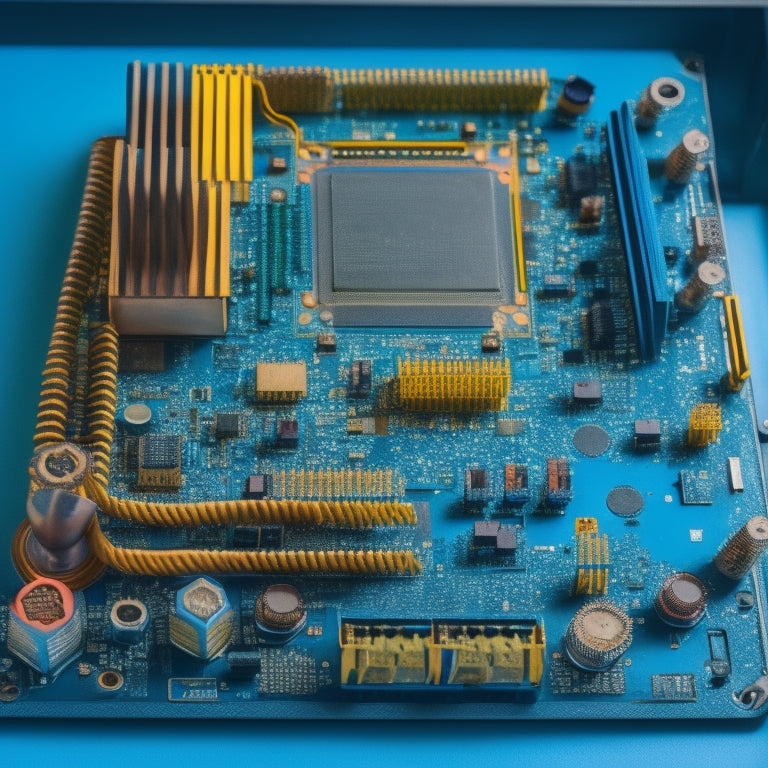

You're likely to encounter socket trays in various electronic devices, from computers to smartphones. A socket tray is a vital component that holds and organizes electrical components, guaranteeing safe and efficient connections.

When it comes to socket tray materials, you'll typically find them made from durable plastics, metals, or a combination of both. The choice of material depends on the specific application, operating environment, and required level of durability.

For instance, metal socket trays are often used in industrial settings where harsh conditions prevail.

During socket tray installation, it's essential to follow proper procedures to guarantee safe and reliable operation. You should carefully select the correct socket tray for your specific application, considering factors such as component compatibility, thermal management, and environmental considerations.

Socket Tray Components and Design

Within a socket tray, you'll typically find several key components working together to ascertain efficient connection and organization of electrical components. These components are carefully designed to ascertain safe and reliable operation.

-

Component materials: Socket trays often feature durable materials like high-impact polystyrene or ABS, which provide excellent resistance to heat, chemicals, and physical stress.

-

Tray configurations: Trays come in various shapes and sizes to accommodate different electrical components and application requirements. You'll find trays with open or enclosed designs, as well as those with built-in dividers or compartments.

-

Socket types: Socket trays can accommodate various types of sockets, including screw-in, snap-in, or press-fit sockets, each designed for specific electrical components and connection requirements.

- Cable management: Many socket trays feature built-in cable management systems, such as cable ties or clips, to keep cables organized and prevent damage or tangling.

How Socket Trays Enhance Safety

You've learned how socket trays are designed to facilitate efficient connection and organization of electrical components. Now, let's investigate how they enhance safety in your electrical systems.

Socket trays prioritize electrical safety by providing a secure and organized way to manage cables and connections. This reduces the risk of electrical shock, short circuits, and fires. By keeping cables tidy and untangled, socket trays also prevent damage to the cables themselves, which can lead to electrical hazards.

Here's a breakdown of how socket trays enhance safety:

| Safety Feature | Description |

|---|---|

| Cable Management | Keeps cables organized, reducing tangles and damage |

| Reduced Risk of Electrical Shock | Prevents accidental contact with live wires |

| Minimized Fire Risk | Reduces the chance of overheating and electrical fires |

| Improved Airflow | Allows for better air circulation, reducing heat buildup |

| Easy Maintenance | Enables quick identification and replacement of faulty components |

Socket Tray Applications and Uses

Socket Tray Applications and Uses

Socket trays are versatile components that find applications in various industries and settings, from residential to commercial and industrial environments. They're designed to provide a safe and organized way to manage electrical connections, making them an essential tool in many different scenarios.

You'll find socket trays in:

-

Data centers and server rooms, where they help to keep complex networks of cables and connections organized and easily accessible.

-

Industrial settings, such as manufacturing facilities and construction sites, where they provide a safe and reliable way to power tools and equipment.

-

Commercial buildings, like offices and retail spaces, where they support the electrical infrastructure and help to reduce the risk of electrical shock or fire.

- Residential homes, where they can be used to manage electrical connections in basements, garages, or other areas where electrical outlets are needed.

When it comes to socket tray installation and maintenance, it's vital to follow proper safety protocols to guarantee a safe and reliable electrical connection.

Benefits of Using Socket Trays

Five key advantages make socket trays an indispensable component in various settings: they enhance safety, promote organization, simplify maintenance, boost productivity, and reduce costs.

By using socket trays, you can greatly minimize the risk of electrical hazards and tripping accidents caused by cluttered cables. This is because socket trays provide a neat and organized way to manage cables, making it easier to identify and access specific outlets.

As a result, you'll spend less time searching for outlets and more time focusing on your tasks, leading to increased productivity. Additionally, socket trays simplify maintenance by allowing you to easily add or remove outlets as needed, reducing the need for costly and time-consuming electrical work.

By promoting socket organization and effective cable management, socket trays can also help you reduce energy costs by minimizing standby power consumption.

Frequently Asked Questions

Can Socket Trays Be Used in Harsh Environmental Conditions?

You can use socket trays in harsh environmental conditions if they're designed with weather resistance and made from durable materials, ensuring they withstand extreme temperatures, moisture, and physical stress, keeping you and your devices safe.

How Often Should Socket Trays Be Inspected and Maintained?

Like a guardian watching over its treasure, you must keep a close eye on your socket trays, inspecting them regularly, ideally every 3-6 months, and following strict maintenance guidelines to guarantee they remain a safe and reliable haven for your connections.

Are Socket Trays Compatible With All Types of Electrical Connectors?

You'll find that socket trays aren't universally compatible with all electrical connectors; you need to ascertain the tray is designed for your specific socket type, as some may only work with certain connector configurations, so always check compatibility for safe connections.

Can Socket Trays Be Customized for Specific Industrial Applications?

You can get custom socket designs that meet specific industrial socket specifications, ensuring a perfect fit for your application; manufacturers can modify tray layouts, materials, and connector types to meet your unique industrial needs, prioritizing safety and efficiency.

Are Socket Trays Available in Various Sizes and Shapes?

You'll find socket trays in various sizes and shapes to suit your needs, with customizable socket tray dimensions and a range of socket tray materials, ensuring a secure fit and ideal performance in your industrial application.

Conclusion

As you grasp the socket tray's purpose, you hold the key to revealing a safer, more efficient workspace. The socket tray is a signal of organization, shining bright amidst the chaos of tools and wires. It's a guardian, protecting you from the dangers of electrical shock and tripping hazards. With every socket securely in place, you'll feel a sense of control and expertise over your workspace, like a conductor leading an orchestra of productivity.

Related Posts

-

Open Storage Bins for Shelving Units

You need open storage bins that integrate seamlessly with your shelving units to boost your organization, productivit...

-

Key Features of a Garage Wall Hanging System

You're looking for a garage wall hanging system that's built to last and adapts to your needs. Look for systems made ...

-

Building Garage Shelves in 7 Easy Steps

You're about to convert your garage into a highly functional storage space by building custom shelves in just 7 easy ...